Garage custom lens referred to as garage piece, set production. Garage customized lens refers to the product that can not be met by the supply of existing pieces and is used to meet the special needs. This kind of lens is different from the ordinary conventional lens, which can not achieve mass production. Garage customized lenses can provide more comprehensive visual solutions, such as customized myopia lenses to beautify the edge and reduce the thickness of the lens edge, customized customized lenses to adapt to the special curvature of the frame, special film, special large diameter lenses, progressive multifocal lenses, prism lenses, etc.

01 -

Garage custom lens use

1. Special photometric processing: such as high myopia, high hyperopia, high astigmatism, special prism lenses, etc. For example, the highest luminosity of the negative lens was -24.00DS and that of the combined column mirror was -4.00D. Ortho lenses are customized up to +13.00DS. Combined column mirror can be customized to +6.00DC.

2. Special surface processing: spherical, aspherical, two-sided aspherical, progressive lens processing with different luminosity, different progressive surface design, and different internal and external surface progressive design. Because the lens design of different face types will bring different visual feelings, it can provide corresponding solutions for people with different visual needs.

3. Special coating film; To achieve different needs of special film customization. For example, add dural film, anti anti antireflection film, hydrophobic film, etc.

4. Mei-thin machining: Mei-thin machining is the lens with special diameter specified, customized to reduce the thickness of the center of the positive lens and the thickness of the negative lens edge. Custom eccentrically designed, elliptical machined lenses. According to the prescription and the shape and size of the frame, the processing technology with the best thickness is adopted, and the most reasonable thickness of the lens is calculated by professional software, so as to make the glasses more beautiful. Usually, the customization system of garage lens can achieve the requirements of beauty and thinness of lens through diameter design, eccentricity design, lens surface system design and so on.

5. Dyeing processing: according to the corresponding needs, full color, progressive color, individual color, polarized light dyeing and other processing.

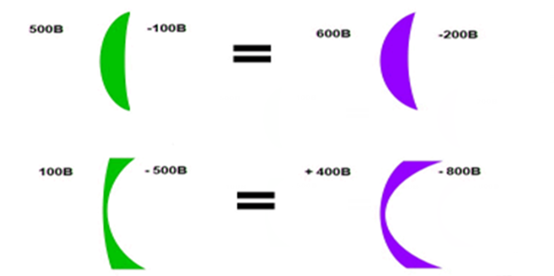

6. Special base curved lens: customize special base curved lens to adapt to special bend frame. For example, fashion people use some sun frames to make myopic sunglasses. According to the frame shape and optometry prescription data, help the wearer to design a reasonable lens surface bend, make the lens match the frame, so that the wearer can present a perfect wearing effect. For example, for the same +4.00D lens, the front surface of +500 turn and the back surface of -100 turn can be selected, and the front surface of +600 turn and the back surface of -200 turn can also be selected. The shape and edge thickness of the lens are completely different between the two schemes.

02 -

Garage custom lens production process

The process mainly includes order collection, calculation of basic data, selection of semi-finished products, verification of basic data, calculation of the shape of the back surface, protective film on the base bending, selection of mold, fixed sucker, rough grinding of the shape of the back surface, fine grinding and polishing of the back surface, unloading inspection, dyeing and hard film, final quality inspection, delivery and other processes.

03 -

Notes for Customization

1. It is recommended that both lenses be customized whenever possible. For example, in the case of anisometropia, one-lens -8.00DS is customized with high refractive index lens, while one-lens -4.00DS is a common conventional non-customized lens. In this case, the center thickness, lens background color and optical imaging effect may be different between the customized lens and the non-customized lens. Therefore, from the perspective of visual health, it is recommended to use the same garage to customize lenses if possible.

2. About the garage, the thick, the thickness of the lens center due to the highly refractive lenses, especially high myopia garage lens using rough grinding production, through the lens at the center of the thickness of the grinding production will certainly is thicker than by mold production, because if the ground thin, first luminosity may not be able to control, the second lens easily broken.

Post time: Sep-26-2022